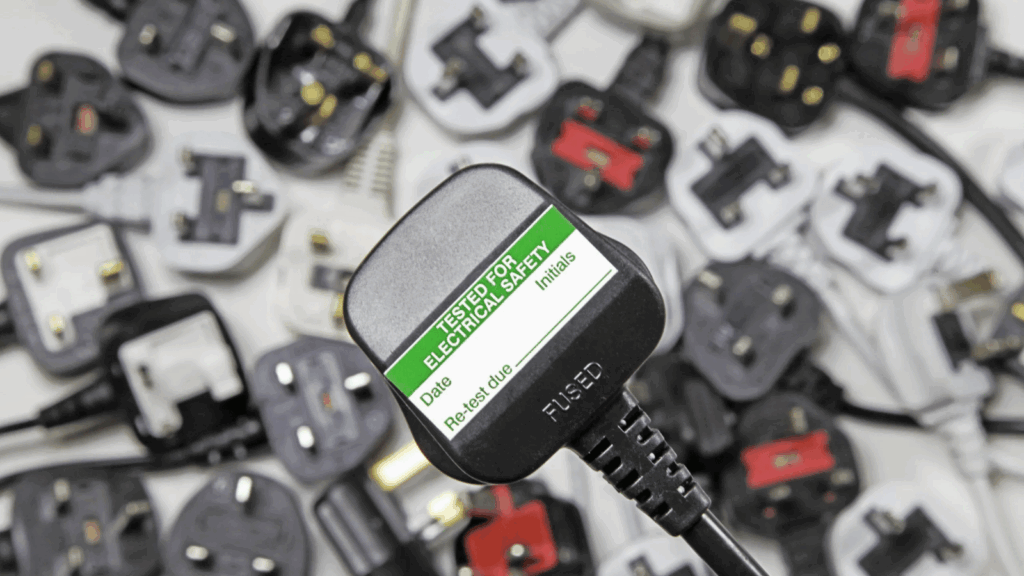

Portable Appliance Testing (PAT) represents a critical safety procedure for businesses across the UK. Understanding both its importance and associated costs helps organisations properly budget for this essential service while maintaining compliance with health and safety regulations.

At DH Electrical Services, we’ve helped countless businesses across the North West navigate the complexities of PAT testing with our transparent pricing and professional approach.

What exactly is PAT testing and why is it necessary?

PAT testing involves examining electrical appliances and equipment to ensure they’re safe to use. The process typically includes visual inspections and electronic testing using specialised equipment. While not explicitly required by law, PAT testing helps businesses meet their legal obligations under the Electricity at Work Regulations 1989, which mandate that all electrical systems be maintained to prevent danger.

Regular PAT testing helps identify potential electrical hazards before they cause accidents, protecting your staff, customers, and premises from electrical fires and other dangers. It’s particularly important in environments where equipment is frequently moved or used in challenging conditions.

What factors influence the cost of PAT testing?

Understanding what drives PAT testing costs helps businesses budget appropriately. Several key factors determine what you’ll pay:

How many appliances need testing?

The most significant cost factor is simply the number of items requiring testing. Most PAT testing companies structure their pricing on a per-item basis, with the cost per item typically decreasing as the quantity increases. A small office might have 20-30 items, while a large manufacturing facility could have hundreds or even thousands.

What types of appliances require testing?

Different appliances demand different testing approaches. Simple items like desk lamps require basic tests, while complex machinery or three-phase equipment necessitates more extensive examination and expertise, potentially increasing costs.

Where is your business located?

Geographic location affects pricing through regional cost variations and travel expenses. London and the South East typically command higher rates than other UK regions, while remote locations might incur additional travel charges.

How accessible are your appliances?

Testing time increases when appliances are difficult to access, require disassembly, or when testing must occur outside normal business hours to avoid disruption. These factors can increase the overall cost.

How frequently does testing need to be completed?

Testing frequency depends on your risk assessment and the nature of your business. High-risk environments like construction sites require more frequent testing than low-risk environments like offices, affecting your annual budget allocation.

What are the average PAT testing costs in the UK?

PAT testing prices can vary significantly based on the factors mentioned above, but understanding current market rates helps with budgeting.

| Service Type | Typical Cost Range | Notes |

|---|---|---|

| Per item rate (standard) | £1 – £3 | For basic items in quantities of 100+ |

| Per item rate (small quantities) | £3 – £5 | For under 50 items |

| Minimum call-out fee | £50 – £100 | Applied for small jobs |

| Daily rate | £150 – £300 | For larger premises with many items |

| Fixed price package | £100 – £500+ | Depends on business size and appliance count |

Many businesses find the most cost-effective option is negotiating an annual contract with a reputable provider like DH Electrical Services. We offer competitive rates with volume discounts and can create customised testing schedules based on your specific needs.

How should you budget for PAT testing?

Effective budgeting for PAT testing requires a strategic approach. Here’s a step-by-step process to help you allocate appropriate funds:

Can you create an inventory of all electrical appliances?

Start by documenting every electrical item in your workplace that requires testing. Categorise them by type, risk level, and usage patterns. This inventory serves as the foundation for your budget calculations and ensures nothing is overlooked.

How do you determine testing frequency requirements?

Work with a qualified electrician to conduct a proper risk assessment of your working environment. This assessment will help establish appropriate testing intervals for different equipment categories. High-risk items might need testing every 3-6 months, while low-risk items might only require annual checks.

Our electrical inspection and testing services can help identify the appropriate testing schedule for your specific situation.

Should you request multiple quotes?

Reach out to several PAT testing providers for detailed quotes based on your inventory and requirements. Look beyond the headline price to consider what’s included—some cheaper services might not provide essential documentation or may use less thorough testing procedures.

Have you calculated your annual PAT testing budget?

Based on quotes and your testing frequency requirements, calculate your annual PAT testing budget. Remember to factor in additional costs such as replacing failed appliances, potential remedial work, and certificate fees.

For businesses with seasonal variations, consider how testing might need to be scheduled around busy periods to minimise disruption.

How can you potentially reduce PAT testing costs?

While PAT testing is an essential expense, several strategies can help manage and potentially reduce costs without compromising safety:

Could combining services save money?

Schedule PAT testing alongside other electrical maintenance work, such as fault finding or LED lighting installation. This approach can reduce call-out fees and overall costs.

Would an annual contract be more economical?

Negotiate an annual contract with a trusted provider rather than arranging one-off testing sessions. Long-term relationships often come with preferential rates and more flexible scheduling options.

Could staff be trained to conduct visual inspections?

Implement a user-check system where staff perform basic visual inspections before using equipment. While this doesn’t replace professional PAT testing, it can identify obvious hazards early and potentially extend the intervals between formal tests for low-risk items.

Our electricians can provide guidance on establishing effective user-check procedures in conjunction with our professional testing services.

Have you optimised your appliance inventory?

Regularly review your appliance inventory to identify and dispose of redundant or rarely used equipment. Fewer appliances mean lower testing costs and reduced risk exposure.

Is rationalising equipment types a viable option?

Where possible, standardise on particular models and brands of equipment. This approach can streamline testing processes and potentially reduce costs through increased efficiency.

What should you look for when choosing a PAT testing provider?

Selecting the right PAT testing partner influences both cost and service quality. Here are critical factors to consider:

Are they properly qualified?

Ensure any provider you consider employs properly trained and qualified engineers. Look for recognised qualifications and accreditations such as City & Guilds 2377 or membership with professional bodies like NAPIT, which all our technicians at DH Electrical Services possess.

Do they provide comprehensive documentation?

Proper documentation is essential for compliance and insurance purposes. Verify that your chosen provider supplies detailed certificates and reports covering all tested items, including those that fail.

What’s their reputation like?

Check reviews, testimonials, and case studies to assess reliability and service quality. Ask for references from similar businesses to yours and follow up with them about their experiences.

How transparent is their pricing structure?

Look for clear, transparent pricing with no hidden fees. Reputable providers like DH Electrical Services will be upfront about their charges and willing to explain exactly what you’re paying for.

Can they work around your schedule?

Testing should cause minimal disruption to your operations. Choose a provider willing to work outside core business hours if necessary, even if this comes with a small premium.

Do they offer advice on failed items?

Value-added services such as advice on repairs or replacements can save significant money over time. The best providers don’t just identify problems but help you solve them efficiently.

At DH Electrical, our expert team doesn’t just perform testing—we provide comprehensive guidance on maintaining electrical safety, including recommendations for fuseboard upgrades when necessary to improve overall system safety.

Get expert PAT testing at competitive rates across the North West

Understanding PAT testing costs helps you budget effectively while maintaining compliance and safety standards. By considering the factors affecting pricing and implementing the strategies outlined in this guide, you can manage PAT testing expenses without compromising on quality or safety.

At DH Electrical Services, we provide transparent, cost-effective PAT testing across the North West, including Liverpool and surrounding areas. Our NAPIT approved technicians deliver thorough testing services with clear documentation and practical advice to help you maintain safe electrical systems.

Contact DH Electrical Services today at 07936 250380 for a no-obligation quote and discover how our comprehensive electrical services can support your business’s safety and compliance needs. From complete house rewires to specialised PAT testing, we’re your trusted electrical partner in the North West.