Portable appliance testing, commonly referred to as PAT testing, is an important safety process that involves both visual and electrical checks on equipment to ensure it remains safe to use in the workplace.

In short, yes, there is a small chance that PAT testing can damage equipment if the incorrect electrical tests or excess currents are applied during the testing process. Using high 25A test currents on electronics with sensitive components that are only designed to handle minimal loads risks overheating and destroying circuit boards.

However, the likelihood of damage is very low when PAT testing is performed properly by qualified technicians following the correct safety procedures and test current selections tailored for each appliance under review. The extensive risks of not doing any PAT testing at all still outweigh the minimal risks from having regulated checks completed periodically.

This article covers the details of PAT testing procedures, where the risks arise, what to do if you suspect damage has occurred, and how to prevent issues in future.

What is PAT Testing and What Does it Involve?

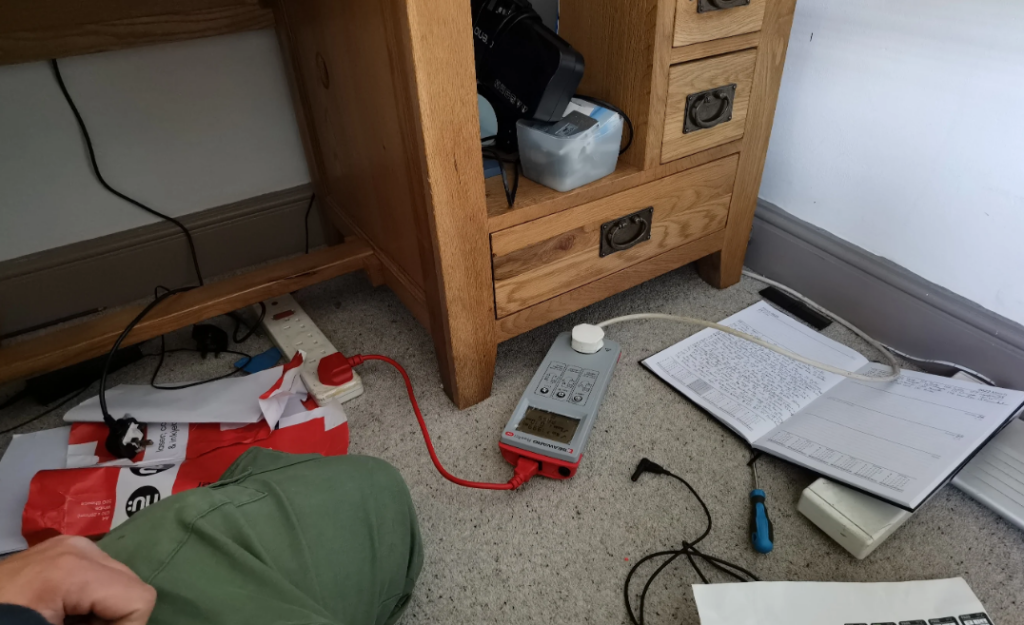

PAT testing consists of a visual inspection of the appliance’s plug, cable, and casing to check for signs of damage. The electrician will then perform a series of electrical safety tests tailored to the specific type of equipment. These tests check key parameters like earth continuity, insulation resistance, and leakage current.

The testing requires the appliance to be powered up or have an electrical charge passed through certain components. This enables measurements to be taken to assess if safety thresholds are being met. While the procedures are non-destructive for most modern appliances, there are certain risks dependent on the age and type of equipment.

Selecting the right tests and appropriate test currents is an important part of the process. While a high 25A test current can provide a more reliable earth continuity reading, it can overload circuits in appliances with sensitive electronic components. IT equipment in particular should only undergo testing using low currents of 200mA or less.

How Can Incorrect PAT Testing Damage Equipment?

There are a few ways that errors during PAT testing can end up causing damage to the very appliances being verified for safety. Key risks include:

- Using excessively high test currents that overheat and destroy circuitry not designed for the surge. Electronics with lower maximum load capacities are at most risk.

- Incorrect test lead connections that create sparks and destroy insulation or sensitive semiconductor components.

- Poor contact pressure when engaging the test button leading to false readings. Operators then attempt repairs on fully functional appliances.

- Slow release of the test button after powering on devices causes fuses to blow or circuits to overload.

In essence, not following equipment limitations and standard operating procedures for the selected electrical tests poses a risk of equipment damage. Lack of training is often a contributing factor for technicians pushing appliance tolerances too far.

What to Do if You Think PAT Testing Has Damaged Equipment

If you suspect an appliance has been damaged in the testing process, follow this procedure:

- Immediately unplug and stop using the equipment in question. Attempting to operate damaged electronics can compound issues or pose additional safety hazards.

- Contact the PAT testing provider to notify them of the possible equipment damage. Ask them to investigate as they may cover repairs if at fault.

- If they confirm issues stemmed from errors during testing, request information on the remediation or replacement process. Financial compensation may also be applicable.

- For unresolved damage disputes, consult an independent electrician to determine if testing was the likely cause based on the nature and location of faults. Their report could support warranty claims.

While rare with competent technicians, it’s important all parties follow up appropriately if PAT testing service errors do occur. Early communication and specific damage details help resolve these situations effectively.

Consequences of Not Getting PAT Testing Done

While PAT testing itself carries a small risk of equipment damage if performed incorrectly, failing to execute regular appliance testing has more significant consequences:

- Untested devices have a much higher likelihood of developing electrical faults over time that could cause fires or electric shocks in the workplace.

- If an appliance has an existing defect that is not identified, using it continuously magnifies the chances of catastrophic failure.

- Any damage resulting from an untested device may void manufacturer warranties due to lack of maintenance records. Repair and replacement costs fall to the business.

The extensive personal safety and property damage risks associated with avoiding PAT testing vastly outweigh the minimal risks from having checks completed by a trained professional. Keeping testing schedules and maintenance logs up to date is crucial for early fault detection.

In summary, PAT testing is a vital process for identifying appliance defects before they cause harm, but incorrect procedures do pose a small risk of equipment damage in rare cases. Following safety protocols tailored to each device’s tolerances minimises any testing risks. Stop using and promptly contact providers if issues seem to occur to determine solutions.

DH Electrical Services – Safe PAT Testing Services in The North West

For professional PAT testing services you can rely on, contact our team of qualified electricians in Liverpool. With over 20 years of experience serving Merseyside homes and businesses, we follow rigorous appliance testing procedures to deliver comprehensive safety reports.

Our electricians select the appropriate test currents and methods to match your different device types, preventing any risk of equipment damage. We issue individual labels and registers to easily track when future re-testing is due across your inventory.

Get in touch today to find out more about protecting your workplace with regular portable appliance testing from our knowledgeable Liverpool electricians.

Read Also:

> What Do You Need To Get PAT Tested?

> A Guide to PAT Testing Risk Assessments