Preparing for an electrical inspection in your commercial property shouldn’t be a last-minute scramble. Whether you’re a business owner, property manager, or facilities director in the North West, understanding what’s involved in a commercial electrical inspection can save you time, money, and potentially significant headaches. Electrical safety isn’t just a box-ticking exercise – it’s a legal requirement that protects your staff, customers, and business from potentially devastating consequences.

The stakes are particularly high for commercial properties. Unlike residential inspections, commercial electrical assessments must account for greater complexity, higher loads, specialised equipment, and stricter compliance standards. Proper preparation makes the difference between a smooth inspection process and an expensive, disruptive ordeal.

What exactly is a commercial electrical inspection?

A commercial electrical inspection, often conducted as part of an Electrical Installation Condition Report (EICR), is a comprehensive assessment of your property’s electrical systems and installations. In the UK, these inspections must comply with BS 7671 (IET Wiring Regulations) and are designed to:

- Identify potential safety hazards – Including fire risks, shock hazards, and other dangerous conditions that could harm people or damage property

- Verify regulatory compliance – Ensuring your property meets current UK electrical standards and building regulations

- Document the condition of electrical systems – Providing a detailed record of your electrical infrastructure’s health

- Recommend necessary improvements – Highlighting any repairs or upgrades needed to maintain safety and compliance

Under UK regulations, commercial properties generally require an EICR every 5 years or when there’s a change of occupancy. However, certain environments with higher risks – such as pools, industrial settings, or public venues – may need more frequent inspections.

Why should you take commercial electrical inspections seriously?

Beyond the obvious safety considerations, there are compelling reasons to prioritize proper electrical inspection preparation:

Legal compliance

The Electricity at Work Regulations 1989 places legal responsibility on employers and property owners to maintain safe electrical systems. Failing to conduct proper inspections can result in significant fines and even criminal prosecution if negligence is proven.

Insurance requirements

Most commercial insurance policies require up-to-date electrical safety certification. Without valid documentation, claims related to electrical incidents might be rejected, leaving your business exposed to potentially ruinous costs.

Business continuity

Electrical faults account for roughly 25% of all commercial fires in the UK. Beyond the immediate danger, the business disruption from even minor electrical issues can be substantial. Regular inspections help identify problems before they escalate.

Staff and customer wellbeing

Your duty of care extends to everyone who enters your premises. Electrical hazards pose risks that responsible business owners simply cannot ignore.

What documentation should you gather before the inspection?

Proper documentation demonstrates your commitment to electrical safety and helps inspectors understand your system’s history. Gather these essential records:

- Previous EICRs and testing certificates – Historical reports provide valuable context and allow inspectors to track changes or deterioration over time

- Electrical installation certificates – Documentation for any new installations or major modifications since the last inspection

- Minor works certificates – Records of smaller electrical jobs completed since the previous assessment

- Circuit charts and distribution board schedules – Up-to-date diagrams showing how your electrical system is configured

- Maintenance records – Documentation of regular electrical maintenance and any repairs

- Fire alarm and emergency lighting test certificates – Evidence that these critical safety systems have been properly maintained

Missing documentation doesn’t necessarily mean starting from scratch. Professional electricians from DH Electrical’s inspection and testing team can help reconstruct records through thorough testing and assessment.

How should you prepare your physical space?

Taking these practical steps before inspection day will make the process more efficient:

Ensure access to all electrical points

Inspectors need unrestricted access to distribution boards, consumer units, junction boxes, and all electrical accessories. Clear away obstacles, remove covers that might impede access, and ensure storage areas containing electrical equipment are accessible.

Schedule around critical operations

Parts of the inspection may require power to be temporarily disconnected. Plan the inspection during off-hours or less busy periods to minimize disruption to your business operations.

Brief relevant staff

Make sure key personnel understand when the inspection will happen and what it involves. This might include facility managers, department heads, security staff, and IT teams who may need to safely power down sensitive equipment.

Address obvious issues in advance

Fix visible problems like damaged outlets, frayed cords, or overloaded power strips before the inspection. This demonstrates proactive maintenance and may prevent certain deficiencies from appearing on your final report.

What will inspectors be looking for in your commercial property?

Understanding the scope of the inspection helps you prepare more effectively. Commercial electrical inspections typically cover:

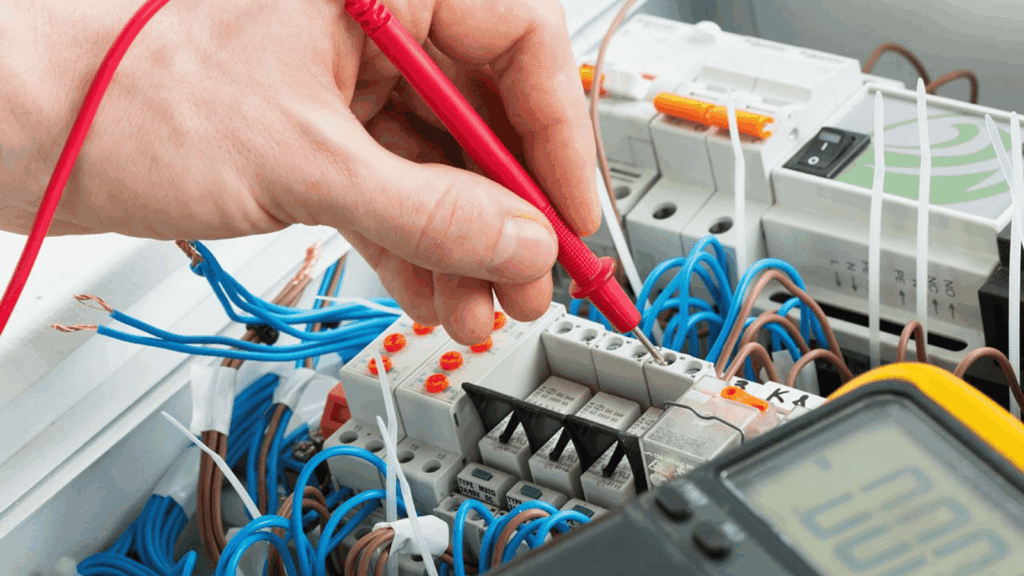

Distribution equipment

Main panels, consumer units, and distribution boards will be thoroughly examined. Inspectors check for proper labeling, sufficient capacity, appropriate protection devices, and signs of overheating or damage.

Wiring systems

Inspectors assess cables for appropriate sizing, correct installation methods, proper insulation, and evidence of physical damage or deterioration. They’ll particularly focus on high-risk areas like damp locations or where wiring might be exposed to physical damage.

Circuits and protective measures

Each circuit will be tested for proper functioning of RCDs (Residual Current Devices), appropriate earthing, correct polarity, and suitable overcurrent protection. Inspectors will also measure insulation resistance and earth fault loop impedance.

Electrical accessories

Switches, sockets, light fittings, and similar components are checked for damage, correct installation, and proper functioning. In commercial environments, inspectors also verify that appropriate IP-rated (Ingress Protection) accessories are used in specialized areas.

Emergency systems

Fire alarm systems, emergency lighting, backup power supplies, and safety shutdown mechanisms undergo particularly rigorous examination. These critical safety systems must function flawlessly during emergencies.

Special installations

Areas with unique requirements – such as medical facilities, hazardous environments, or high-voltage installations – face additional scrutiny against their specific regulatory standards.

What common issues do inspectors find in commercial properties?

Being aware of frequent problems helps you address them proactively:

- Insufficient socket provision – Leading to dangerous daisy-chaining of extension leads and adaptors

- Outdated protective devices – Older fuses and circuit breakers that don’t meet current safety standards

- DIY modifications – Unprofessional alterations that violate regulations or create hazards

- Overloaded circuits – Systems carrying more current than they were designed to handle

- Missing RCDs – Lack of these crucial devices that prevent electric shock by quickly disconnecting circuits

- Poor maintenance – Accumulated dust, loose connections, and damaged components that create fire hazards

- Improper earthing – Inadequate connections that compromise safety protection

- Water ingress – Evidence of moisture affecting electrical installations

Addressing these common issues before your inspection can significantly improve your results. Our fault finding specialists can identify and resolve these problems efficiently.

How can portable appliance testing complement your electrical inspection?

While fixed wiring inspections focus on your building’s electrical infrastructure, don’t overlook portable appliances. These everyday items can pose significant risks:

Portable Appliance Testing (PAT) examines movable electrical equipment such as computers, printers, kettles, and power tools. While not legally mandatory, PAT testing is the most practical way to comply with the Electricity at Work Regulations requirement to maintain electrical equipment in a safe condition.

Schedule PAT testing to coincide with your broader electrical inspection for comprehensive coverage of all electrical safety aspects. For many businesses, this combined approach provides peace of mind and complete documentation of electrical safety compliance.

What happens if problems are found during the inspection?

Understanding the classification system helps you prioritize remedial work:

Classification codes

EICR findings are categorized by severity:

- C1 (Danger Present) – Immediate risk requiring instant attention. The inspector may disconnect dangerous circuits on the spot

- C2 (Potentially Dangerous) – Urgent issues that need prompt attention but don’t present immediate danger

- C3 (Improvement Recommended) – Non-urgent suggestions for better practice or future enhancement

- FI (Further Investigation) – Areas where additional testing or assessment is needed

C1 and C2 issues must be addressed to receive a satisfactory EICR. Our team can provide comprehensive remedial services, from fuseboard upgrades to complete rewiring services.

How do you choose the right electrical inspection provider?

Not all electrical contractors are equally qualified to perform commercial inspections. Look for:

- Appropriate certifications – Ensure they hold relevant qualifications and are registered with recognized bodies like NAPIT

- Commercial experience – Verify they regularly work with similar business properties

- Insurance coverage – Confirm they carry adequate professional indemnity and public liability insurance

- Clear communication – Choose providers who explain findings in understandable terms and provide detailed documentation

- Local expertise – Providers familiar with local building regulations and requirements

DH Electrical Services meets all these criteria with NAPIT-approved technicians and decades of commercial inspection experience across the North West.

How can you maintain compliance between inspections?

Electrical safety isn’t a one-time event but an ongoing process:

Implement a maintenance schedule

Regular checks between formal inspections can identify developing issues early. Create a calendar for visual inspections of key components and schedule preventative maintenance.

Staff training

Ensure employees understand basic electrical safety and know how to report concerns. Simple awareness can prevent major problems.

Consider modern solutions

Technologies like LED lighting installations and WiFi security systems can improve safety while reducing energy costs.

Keep records current

Document all electrical work, no matter how minor. This creates a valuable history that helps future inspectors understand your system’s evolution.

Ready to ensure your commercial property’s electrical safety?

Preparing properly for your commercial electrical inspection demonstrates your commitment to safety, compliance, and professional business operations. With the right approach, you can transform this regulatory requirement into an opportunity to improve your property’s efficiency and safety.

DH Electrical Services provides comprehensive commercial electrical inspections across Liverpool and the North West. Our NAPIT-approved electricians deliver thorough assessments at competitive rates without compromising on quality or attention to detail.

Whether you need a scheduled EICR, remedial work following an inspection, or advice on improving your electrical systems, our team is ready to help. Contact our Liverpool electricians today at 07936250380 to schedule your commercial inspection or discuss your electrical safety requirements.