In the world of electrical safety, comprehending the distinctions between Class I and Class II equipment is crucial, especially when it comes to Portable Appliance Testing (PAT). At DH Electrical, we believe that knowledge is power – quite literally in this case! Let’s dive into the intricacies of these equipment classifications and why they matter for your safety.

What is PAT Testing?

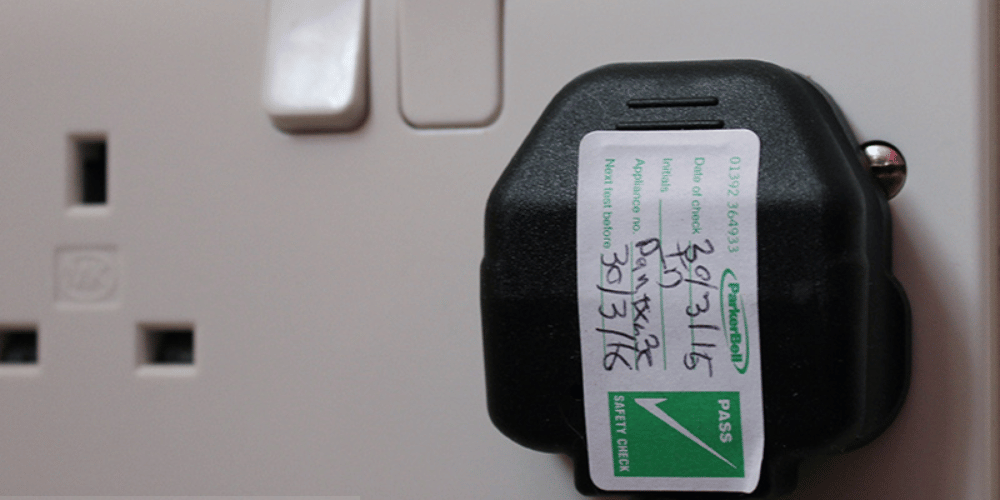

Portable Appliance Testing (PAT) is a vital safety procedure that involves inspecting and testing electrical appliances to ensure they’re safe for use. This process helps prevent electrical accidents, fires, and other hazards in both residential and commercial settings.

PAT testing involves several key steps:

- Visual inspection

- Earth continuity testing (for Class I appliances)

- Insulation resistance testing

- Functional checks

- Lead polarity checks (where appropriate)

Did you know? PAT testing isn’t just about ticking boxes – it’s about safeguarding lives and property.

Basic Protection and Fault Protection: The Cornerstones of Electrical Safety

At the heart of electrical safety lie two fundamental concepts: basic protection and fault protection. These principles form the foundation for the classification of electrical equipment.

Basic Protection

Basic protection is the first line of defence against electrical hazards. It prevents direct contact with live electrical parts under normal operating conditions. Think of it as the ‘don’t touch’ barrier between you and the electricity.

Examples of basic protection include:

- Insulating materials covering live parts

- Barriers or enclosures preventing access to live parts

- Positioning live parts out of reach

Fault Protection

Fault protection, on the other hand, is the backup plan. It kicks in when basic protection fails, providing an additional layer of safety to prevent electric shocks.

Fault protection methods include:

- Automatic disconnection of supply (used in Class I equipment)

- Double or reinforced insulation (used in Class II equipment)

- Electrical separation

- Extra-low voltage

Class I Equipment: Earth Connection Protection

Class I equipment relies on a combination of basic insulation and an earth connection for protection. Let’s break down how this works and explore some common examples.

How Class I Equipment Works

- Basic Insulation: The first layer of protection is provided by insulating materials that cover live parts.

- Earth Connection: The metal casing or exposed conductive parts are connected to the earth via the earth wire in the power cord.

- Fault Scenario: If a fault occurs and the basic insulation fails, the earth connection provides a low-resistance path for the fault current.

- Circuit Protection: The high fault current triggers the circuit protection device (like a fuse or circuit breaker), cutting off the power supply.

The Importance of Earth Connection

The earth connection in Class I appliances serves several crucial functions:

- Fault Current Diversion: It provides a safe path for fault currents to flow, preventing the user from becoming part of the circuit.

- Voltage Limitation: It helps limit the voltage that can appear on accessible metal parts.

- Triggering Protection Devices: The earth connection ensures that fault currents are high enough to trigger circuit breakers or blow fuses quickly.

Examples of Class I Appliances

Class I appliances are typically larger household items or those with metal casings. Some common examples include:

- Refrigerators

- Washing machines

- Electric ovens

- Kettles

- Toasters

- Some power tools with metal casings

Safety Tip: Always ensure the earth pin on the plug of Class I appliances is intact and not damaged.

Class II Equipment: Double Insulation Protection

Class II equipment takes a different approach to safety, relying solely on insulation for protection. This design eliminates the need for an earth connection.

How Class II Equipment Works

- Basic Insulation: Like Class I, there’s an initial layer of insulation covering live parts.

- Supplementary Insulation: A second layer of insulation provides additional protection.

- No Earth Connection: Class II appliances don’t require an earth connection for safety.

- Fault Scenario: If the basic insulation fails, the supplementary insulation continues to protect the user.

The Advantages of Double Insulation

Double insulation offers several benefits:

- Increased Safety: Two layers of insulation provide robust protection against electric shock.

- Simplified Wiring: No earth wire means simpler internal wiring and a two-pin plug.

- Versatility: Class II appliances can be used safely even in environments where proper earthing isn’t available.

- Reduced Maintenance: With no earth connection to check, maintenance can be simpler.

Examples of Class II Appliances

Class II appliances are often smaller, portable devices or those with plastic casings. You might recognise these common examples:

- Hair dryers

- Electric drills

- Laptop power supplies

- Television sets

- Many small kitchen appliances

Pro Tip: Look for the double-square symbol (⧃) on the rating plate to identify Class II appliances.

PAT Testing Procedures for Class I and Class II Appliances

The testing procedures for Class I and Class II equipment differ due to their distinct protection methods. Let’s explore how we approach testing each class:

Testing Class I Equipment

- Visual Inspection: We start with a thorough visual check for any obvious damage or wear.

- Check for frayed cords, loose parts, or damage to the casing

- Inspect the plug for any signs of overheating or damage

- Ensure the correct fuse is fitted

- Earth Continuity Test: This crucial test ensures the earth connection is intact and has low resistance.

- Typically, we look for a resistance of less than 0.1 ohms for leads up to 5 meters

- For longer leads, we allow an additional 0.1 ohms per extra 5 meters

- Insulation Resistance Test: We check the integrity of the basic insulation.

- The appliance should have a resistance of at least 1 megohm at 500V DC

- For sensitive electronic equipment, we may use a lower test voltage

- Functional Test: Finally, we operate the appliance to ensure it works correctly.

- This includes checking for any unusual noises, smells, or heat generation

Testing Class II Equipment

- Visual Inspection: As with Class I, we begin with a careful visual examination.

- Pay special attention to the integrity of the outer casing, as this forms part of the insulation

- Insulation Resistance Test: This test is particularly important for Class II appliances, as insulation is their primary protection.

- We typically look for a resistance of at least 2 megohms at 500V DC

- For appliances with sensitive electronics, we may use a lower test voltage or alternative methods

- Functional Test: We operate the appliance to verify its proper functioning.

- This includes checking all switches and controls work as expected

Remember: The absence of an earth continuity test for Class II appliances doesn’t mean they’re safer – it’s just a different safety approach.

Importance of Proper Classification and Testing

Understanding the differences between Class I and Class II equipment is not just academic – it’s crucial for ensuring the safety of users and the longevity of the appliances. Proper classification and regular testing help:

- Prevent electrical accidents and fires

- Identify potential faults before they become dangerous

- Ensure compliance with health and safety regulations

- Maintain the efficiency and lifespan of electrical equipment

The Role of Regular Testing

Regular PAT testing is essential for several reasons:

- Early Fault Detection: Regular tests can identify issues before they become serious hazards.

- Legal Compliance: Many workplaces are required by law to ensure their electrical equipment is safe.

- Insurance Requirements: Some insurance policies require regular PAT testing as a condition of coverage.

- Cost Savings: Identifying and fixing minor issues early can prevent more costly repairs or replacements later.

- Peace of Mind: Knowing your appliances are safe provides reassurance to users and property owners alike.

At DH Electrical, we understand the intricacies of electrical safety and the importance of proper PAT testing. Our team of expert electricians in The North West, including our skilled electricians in Liverpool, are equipped with the knowledge and tools to ensure your appliances are safe and compliant.

Don’t leave your electrical safety to chance. While understanding the basics of Class I and Class II equipment is valuable, nothing beats the expertise of a professional.

Contact DH Electrical today to schedule your PAT testing and enjoy the peace of mind that comes with knowing your electrical appliances are in safe hands. Your safety is our priority – let us help you maintain it.