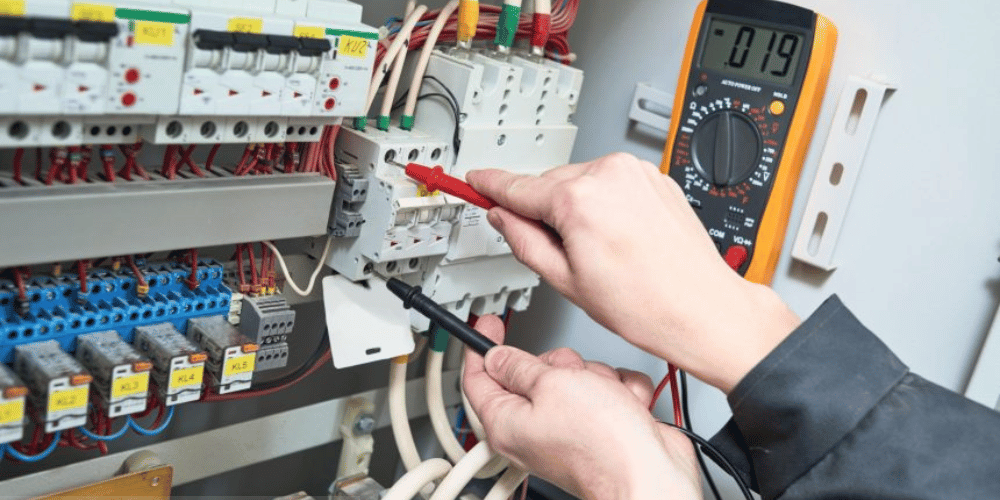

High voltage testing is a critical aspect of electrical safety and maintenance that requires specialised knowledge, equipment, and expertise. At DH Electrical, we understand the importance of this process and its role in ensuring the safety and efficiency of electrical systems.

This blog post will delve into the intricacies of electrical testing and inspections, and specifically high voltage testing, its significance, and why it’s crucial to leave this task to professionals.

Defining High Voltage

Before we dive into the testing procedures, it’s essential to understand what constitutes high voltage. Generally speaking, high voltage refers to:

- Alternating Current (AC): Voltages exceeding 1000 Volts

- Direct Current (DC): Voltages surpassing 1500 Volts

These elevated voltage levels are commonly found in various applications across the globe, including:

- Power generation facilities

- Electrical distribution networks

- Railway systems

- Petrochemical refineries

- Large-scale industrial complexes

- Certain commercial properties

The Heightened Risks of High Voltage

While all electrical systems pose potential dangers, high voltage environments present significantly increased hazards. The primary risks associated with high voltage include:

| Risk Factor | Description |

| Electrocution | Severe or fatal electric shock due to contact with live parts |

| Arc Flash | Dangerous release of energy caused by electrical faults |

| Burns | Serious thermal injuries from electrical current or arc flash |

| Equipment Damage | Potential destruction of valuable electrical infrastructure |

It’s a common misconception that electrical harm only occurs through direct contact with live components. In reality, high voltage electricity can travel through the air via a phenomenon known as arcing. This capability makes high voltage systems particularly treacherous and necessitates specialised testing equipment with extended probes to maintain a safe distance between the operator and the system under examination.

The Importance of High Voltage Testing

High voltage testing serves several crucial purposes:

- Safety Assurance: Verifies that electrical systems are operating within safe parameters

- Fault Detection: Identifies potential issues before they lead to failures or accidents

- Compliance: Ensures adherence to regulatory standards and industry best practices

- Performance Optimisation: Helps maintain peak efficiency of electrical systems

- Longevity: Contributes to the extended lifespan of electrical equipment

Common High Voltage Testing Procedures

While there are numerous forms of high voltage testing, some of the most frequently performed procedures include:

- Voltage Detection and Indication: This fundamental test confirms the presence or absence of voltage in a specific part of a high voltage system. It’s particularly crucial during the process of ‘safe isolation’ before any work is carried out on or near high voltage systems.

- Insulation Resistance Testing: Measures the resistance of insulating materials to ensure they can withstand the high voltages present in the system.

- Partial Discharge Testing: Detects and measures small electrical sparks that can occur in insulation materials, potentially indicating degradation or impending failure.

- Power Factor Testing: Assesses the overall condition of electrical insulation in high voltage equipment.

- Circuit Breaker Testing: Evaluates the performance and reliability of high voltage circuit breakers, which are critical for system protection.

Essential Equipment for High Voltage Testing

Conducting high voltage tests requires specialised equipment designed to handle elevated voltage levels safely. Some key pieces of equipment include:

- High Voltage Detectors and Indicators: These devices, such as the Seaward KD1E, are used to confirm the presence or absence of voltage in a system. They typically feature both neon and digital systems for redundancy and clarity.

- Proving Units: Devices like the Seaward PH3 generate a known high voltage source to verify the proper functioning of detectors and indicators before and after testing.

- Insulation Resistance Testers: Specialised metres that apply a high voltage to measure insulation resistance.

- Partial Discharge Detectors: Sophisticated instruments that can detect and analyse partial discharges in high voltage equipment.

- Power Factor Test Sets: Equipment used to measure the power factor of insulation in high voltage apparatus.

The Critical Three-Step Safe Isolation Process

When working with high voltage systems, following a rigorous safety protocol is non-negotiable. The three-step safe isolation process is a cornerstone of high voltage safety:

- Prove the Indicator: Use a proving unit to verify that the voltage detector or indicator is functioning correctly.

- Test the System: Use the verified detector to confirm that the system to be worked on is truly ‘dead’ or de-energised.

- Re-prove the Indicator: After testing the system, use the proving unit again to ensure the detector remains functional throughout the testing process.

This meticulous approach minimises the risk of false readings that could lead to dangerous situations. It accounts for potential equipment failures and provides confidence in the safety of the system before any work begins.

The Expertise Required for High Voltage Testing

High voltage testing is not a task for the uninitiated. It demands:

- In-depth knowledge of electrical systems and high voltage phenomena

- Comprehensive understanding of safety protocols and risk assessment

- Familiarity with relevant standards and regulations

- Proficiency in using specialised high voltage testing equipment

- Experience in interpreting test results and diagnosing potential issues

Given the complexity and inherent dangers of high voltage systems, it’s crucial to emphasise that this work should only be undertaken by qualified professionals. Attempting high voltage testing without proper training and authorisation can lead to severe injuries, fatalities, and significant property damage.

Conclusion: Trust the Experts for High Voltage Testing

High voltage testing is a critical aspect of electrical safety and system maintenance that requires specialised knowledge, equipment, and experience. At DH Electrical, our team of skilled electricians in the North West, including our expert electricians in Liverpool, are fully trained and equipped to handle all aspects of high voltage testing safely and efficiently.

Don’t take unnecessary risks with high voltage systems. Whether you need routine testing, fault diagnosis, or emergency services, trust the professionals at DH Electrical to ensure your electrical systems are safe, compliant, and operating at peak efficiency.

Contact us today to learn more about our high voltage testing services and how we can help safeguard your electrical infrastructure.